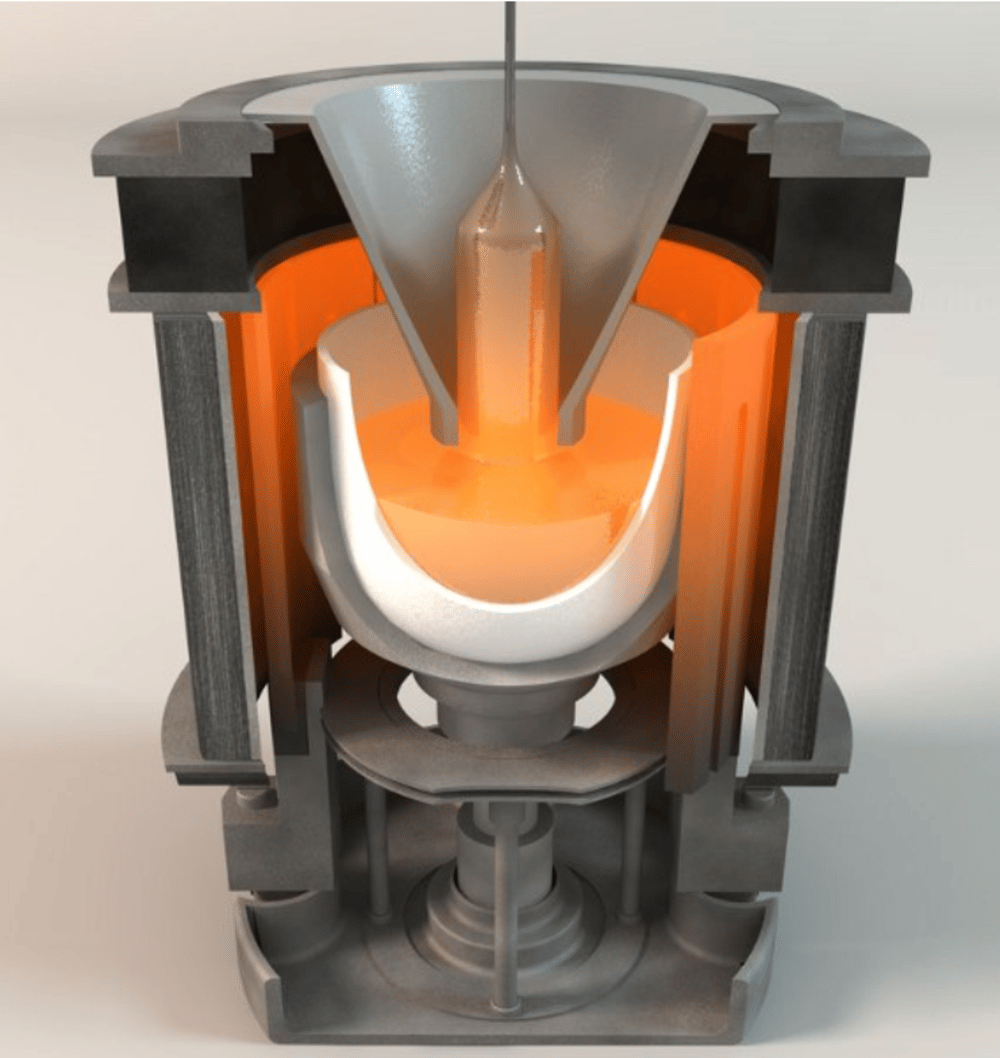

Pure Silicon Nitride for mono-Si Crystallization Furnaces

Silicon nitride is a hard and inert material with excellent chemical and mechanical properties, and stable at high temperatures. It can replace graphite hot-zone components in CZ silicon crystallization furnaces.

Our Reaction-bonded Silicon Nitride (RBSN)

are made through a novel process that involves direct reaction of pure silicon powders with nitrogen gas without catalysts. As a result, we are able to produce pure (5N grade) silicon nitride materials that are very suitable as parts for PV mono-Silicon (CZ) crystallization furnaces.

Pure Advanced Ceramic Materials

CIFTJA Technologies developed a novel process for production of pure SiN materials with:

Our Process

Production of SiN ceramic products

Our manufacturing process of silicon nitride materials goes through two steps:

(i) 3D Printing of the material “green-body” where silicon powders are mixed with an organic binder and then are 3D-printed into a component designed according to customer requirements. By this technique, accurately dimensioned shapes can be made without expensive and time consuming finishing operations.

(ii) the green-body is fired in a nitration reactor under nitrogen gas at controlled temperatures and pressure, giving thus the final silicon nitride product with excellent properties.

3D printing of silicon powder

Manufacturing of the product shape and geometry is carried out by a 3D printing process developed by CIFTJA in cooperation with NTNU and co-financed by RFF Trøndelag.

Our 3D Printing makes a much better use of raw materials and results with less cuts and rejects during the manufacturing process and hence, has high production yield. In addition, it is easier and less labor intensive.

Nitration of silicon

This process step is crucial in making of very pure silicon nitride (SiN) materials.

Nitration of silicon powders without adding catalysts to help the chemical reaction of silicon with nitrogen gas, invented by Dr. A. Ciftja was previously employed by Steuler Solar Technology AS to produce industrial scale SiN crystallization crucibles for PV multicrystalline silicon.

Our team

The team behind this invention has long experience in PV silicon and ceramics industries, research and academia.

Arjan Ciftja, Ph.D.

CEO & CTO

Jan Sandmo

COO & CFO

Johnny Sørensen

Manufacturing Manager